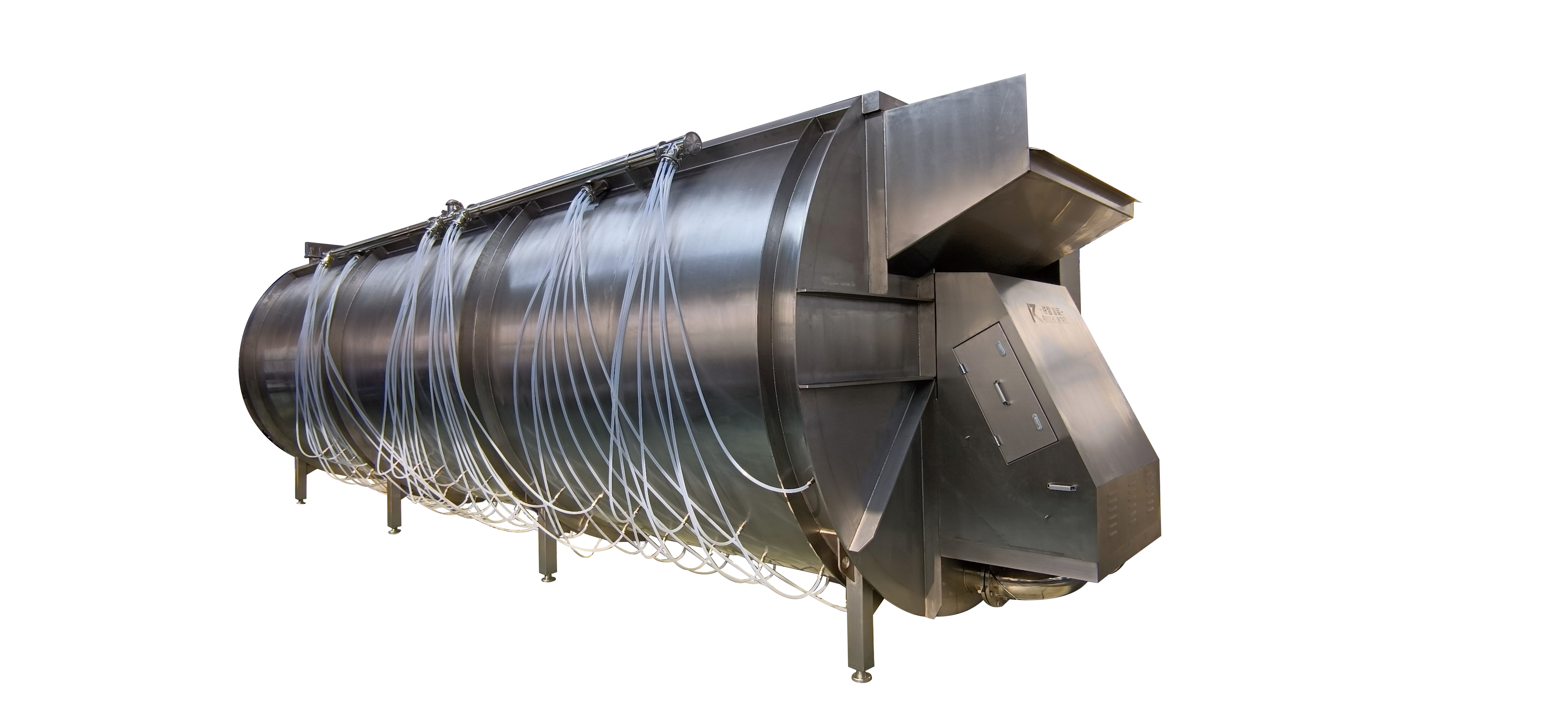

The rotary chilling is one of the main equipments in the poultry slaughtering production line. It is used to cool, clean and sterilize the poultry carcass after the poultry is eviscerated.

The tree-shaped explosion pipeline arrangement is adopted to ensure the balance of wind pressure and air volume at all points inside machine.

The balanced design of each explosion point on the tank body ensures that the passing poultry carcasses are fully stirred and the poultry carcasses are not refluxed.

According to these two designs, the machine can ensures that the passing poultry carcass can obtain the best cooling effect and water absorption rate under the condition of the same poultry-water ratio per unit time.

The design of the helical poultry body propeller ensures that when the water flow is different, the helical blades will not block the aeration and float below it during the process of pushing the poultry body forward.

The sealing structure of special material is used between the main shaft of the driving end and the end plate, and the service life of the seal can be as long as more than 10 years, which avoids the problem of water leakage caused by the aging of the rubber seal ring and needs to be replaced.

A poultry cavity with water backflow device is arranged under the outlet chute, which reduces the amount of high-temperature water in the previous equipment being brought into the next low-temperature equipment.

The backflow structure under the outlet chute can also realize the counterflow function between the pre-cooling units. When it is necessary to realize the flow of clean water in the equipment in the low-temperature zone to the equipment in the high-temperature zone, it is only necessary to adjust the water level of the corresponding equipment. In addition, connect the sink or water pipe.

The food-grade pneumatic hose is used instead of the plastic clamping tube, which is beautiful and hygienic, with a greatly improved service life and easy replacement.

No retention design is adopted between the spiral blades and the spiral blades, between the spiral blades and the pull-out mechanism under the middle hanging beam, and no poultry remains when the water is released.

A screw spindle speed monitoring device is installed; the spindle speed can be fed back to the control system of the unit in real time, and an alarm can also be issued when the screw spindle fails to stop, so as to prevent a certain section of the unit from being blocked.

A pre-cooling water temperature detection device is provided, which can transmit the pre-cooling water temperature to the display device in real time.

The pre-cooling unit adopts the control method of PLC+touch screen. The real-time status of the pre-cooler can be displayed on the touch screen. The speed of the equipment can be adjusted by setting the pre-cooling time. One-button progressive start and stop, spindle drive and discharge can be set. Drive chain control, drive fault alarm.

Main material: 304 Stainless steel

Tank thickness: 4mm

Reinforcing ribs thickness

double reinforcing ribs on both sides of tank body outrigger: 12mm

Spiral blade thickness: 4mm

304 Stainless steel Pull-out mechanism,thickness of turning chicken plate: 4mm

End plate thickness: 4mm

Tree blower structure: Main drive motor brand Siemens, reducer brand Chuanshi

Discharge drive gear motor brand NORD

Working Length: 6~15.0m

Overall length: 7.56~ 16.56m

Tank outer diameter: 3.2m

Tank inner diameter: 3.0m

Spiral blade diameter: 2.92m

water capacity: 5.5m³/ extension meter

Main air pipe diameter: 102mm

Motor power: 1.5+1.5=3.0kw