Recently, Sinolion Machinery, a subsidiary of MOON-TECH, was selected into the list of key laboratories in Jinan, and its products were also successfully selected into the list of first-class equipment in Jinan. Sinolion Machinery Co., Ltd. is a high-tech enterprise that provides customers with post-process packaging solutions including product boxing, transportation, testing, palletizing, wrapping and packaging based on intelligent packaging equipment. By integrating the Internet of Things technology to realize product data collection, material information tracking, warehousing and logistics scheduling, it realizes the intelligent circulation of unit products from manufacturing completion to the hands of users.

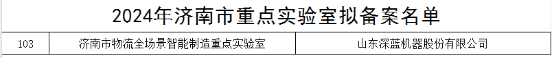

Selected into the list of Jinan Key Laboratories

The Jinan Science and Technology Bureau announced the proposed registration list of Jinan Key Laboratories in 2024. After public application, district and county review and recommendation, expert review, on-site inspection and other processes, Sinolion Machinery Co., Ltd.'s " Jinan Logistics Full-Scenario Intelligent Manufacturing Key Laboratory" was successfully selected into the list, obtained the qualification to build a municipal key laboratory, and was included in the sequence management of Jinan Key Laboratories.

Sinolion Machine's "Jinan Logistics Full-Scene Intelligent Manufacturing Key Laboratory" optimizes and upgrades packaging efficiency and equipment operation smoothness based on the company's existing full-chain production line intelligent packaging equipment, ensuring efficient and stable operation of the entire production line packaging equipment, exploring a new generation of production line packaging models, and creating new technologies that lead the development of the industry. Sionlion studied how to use the Internet of Things and sensor technology to achieve traceability of post-production logistics, including tracking the source, manufacturing process, storage conditions, and transportation of production lines. It not only helps with quality control, but also meets the requirements of regulations and quality standards, thereby improving product quality and customer satisfaction. By integrating warehouse management software with intelligent scheduling algorithms, the system can monitor and analyze the progress and resource utilization of various tasks in the warehouse in real time, so as to intelligently formulate and adjust the allocation of tasks to ensure efficient execution in a dynamically changing environment.

In the future, Sinolion Machinery will gradually enhance the company's independent innovation capabilities, increase investment in technological research and development based on the existing advanced equipment and advanced processes, develop new products and new processes according to market demand, grow through development, and ultimately achieve the optimization of technological achievements and large-scale and industrialized production of project products, and establish a key laboratory for full-scenario intelligent manufacturing in Jinan Logistics with high management level and strong technological innovation capabilities.

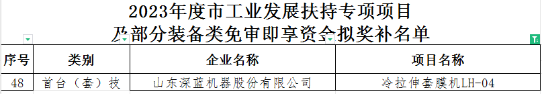

Cold Stretch Wrapping Machine LH-04

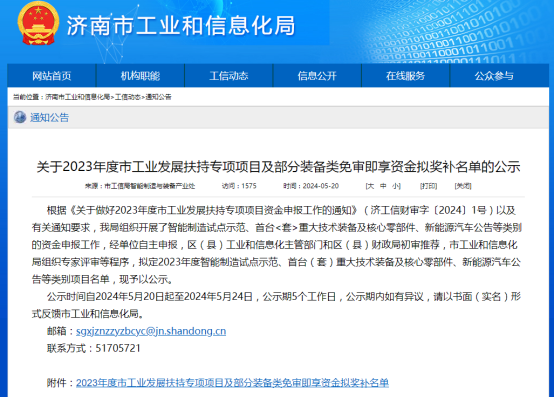

The product was successfully selected as the first set in Jinan City

The Jinan Municipal Bureau of Industry and Information Technology announced the list of proposed awards and subsidies for the city's special projects to support industrial development and some equipment-related funds that are exempt from review in 2023. Among them, Shandong Sionlion Machinery Co., Ltd.'s "Cold Stretch Wrapping Machine LH-04" product was selected into the list of the first set of technical equipment and key core components.

This product is a high-performance cold stretch wrapping equipment. Based on the theoretical calculation of cold stretching tensile force, the analysis of the influence of cold stretching ratio on film structure and performance, and the analysis of the influence of stretching rate on film structure, a film breakage detection mechanism system has been developed. It can detect film breakage in time and alarm during the stretching process. The stretching rate and stretching position of the hood are accurately controlled through the synchronous control of the motor to ensure the quality of hood packaging. The top of the stack is flat after hooding, and the tension on the four sides is balanced to achieve packaging of goods.

The operating system of the cold stretch wrapping machine has complete production operation data records, providing more comprehensive and detailed data for production management. The operating system also has remote detection and data update functions, which improves the efficiency of routine fault detection and maintenance and reduces production costs.

Advantages of cold shrink film packaging:

Compact packaging, economical and flexible, high production efficiency

Low cost, can replace cartons, convenient for outdoor storage

Excellent transparency, beautiful appearance

Good safety performance, non-toxic and odorless, waterproof and dustproof

The packaging is firm, weather-resistant, stable and highly puncture-resistant

Especially suitable for cables, household appliances, food, etc. with high cleanliness requirements

This product has currently obtained 1 invention patent, 8 utility model patents and 1 software copyright registration certificate related to this project. The Shandong Equipment Manufacturing Industry Association organized relevant technical experts to appraise the declared product, and the overall technology of the declared product has reached the domestic leading level.